Nashville Wire Products machinery provides high-quality, high-volume capabilities.

Capabilities

Our state-of-the-art machinery enables us to provide high-quality, high-capacity output. From simple executions to complex program needs, we deliver seamlessly. Clients rely on us to help strengthen their brand performance.

It’s All In-House.

- Engineering geared toward efficient manufacturing techniques

- Prototypes for approval prior to production

- Procurement specialists to negotiate best raw material costs

- Vertical integration with raw material source

- State-of-the-art manufacturing equipment to lend precision and efficiency

- Automation for speed-to-market

- US locations reduce transit times and distribution expense

Producing the products you interact with daily.

Our State-of-the-art Machinery

CNC Wire Forming

Bends solid wire up to .375 inches in diameter, we offer CNC wire forming with both coil-feed and magazine-feed systems, capable of producing a wide variety of 2-dimensional and 3-dimensional shapes.

Electro Plating

Offers continuous, state-of-the-art, environmentally friendly electroplating that meets and exceeds U.S. standards.

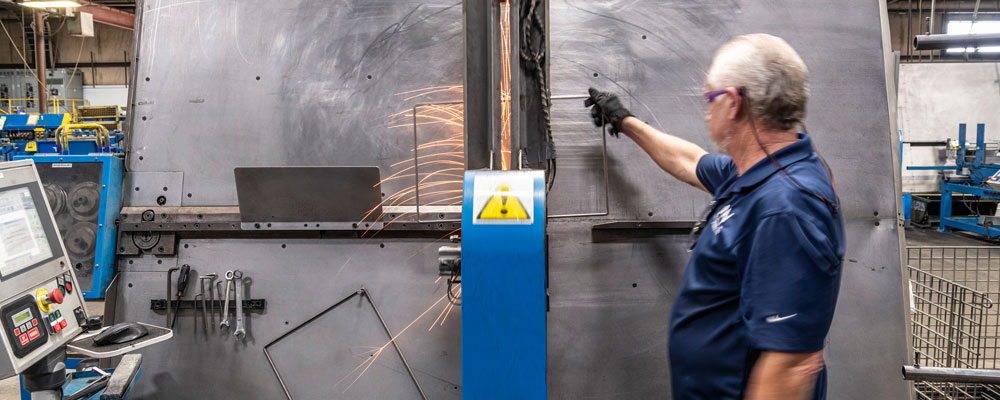

Laser Cutting

Creates high-precision and high-capacity metal stamping with better control, better output and complete consistency.

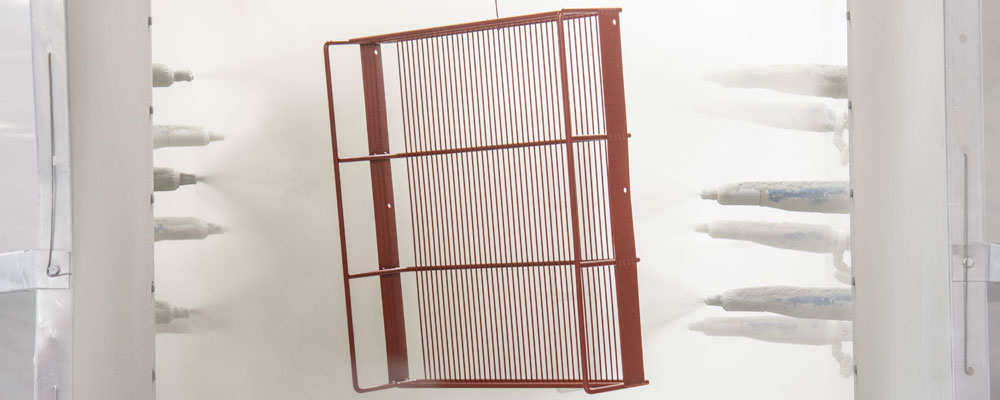

Powder Coating

Operates state-of-the-art powder coating systems that clean and prepare the parts, apply the dry powder and heat cure the parts in a variety of colors and textures.

Sheet Metal Fabrication

Creates sheet metal fabrications for nearly any application, with high precision and to the highest tolerances.

Tube Forming and Fabrication

Forms and fabricates tubular parts and tube components of all sizes, with better bends and faster turns.

Warehousing And Distribution

Provides customers with complete logistics solutions, including dedicated warehousing and just-in-time shipping.

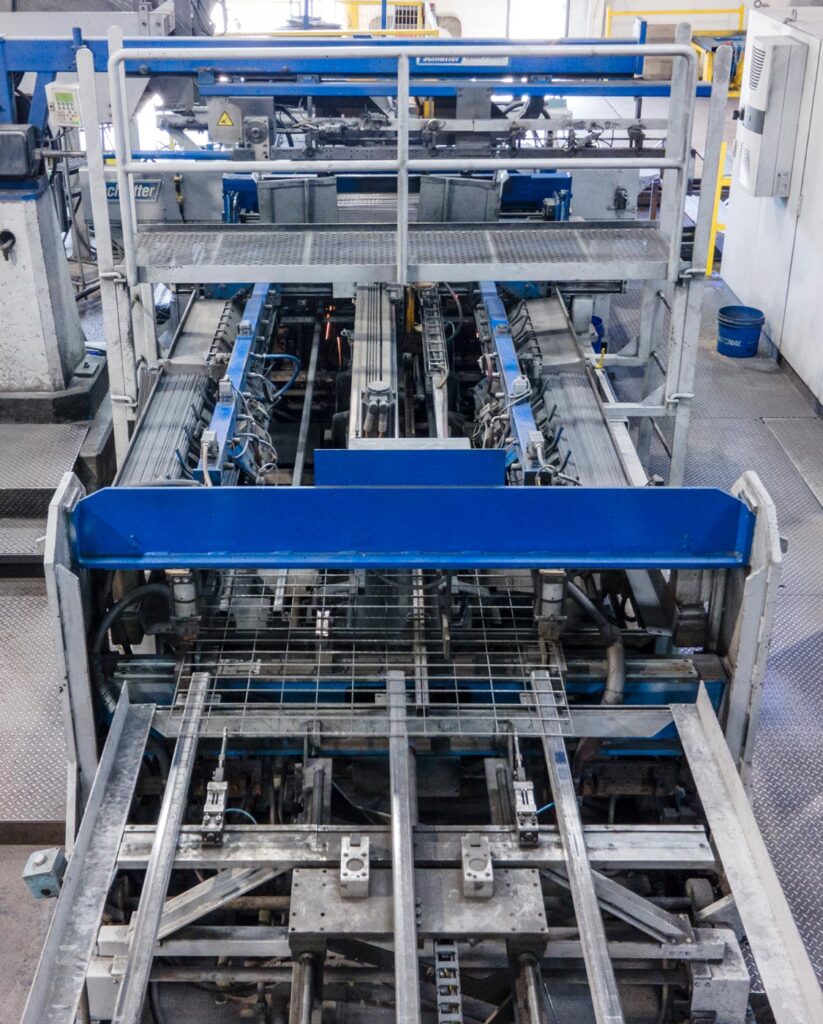

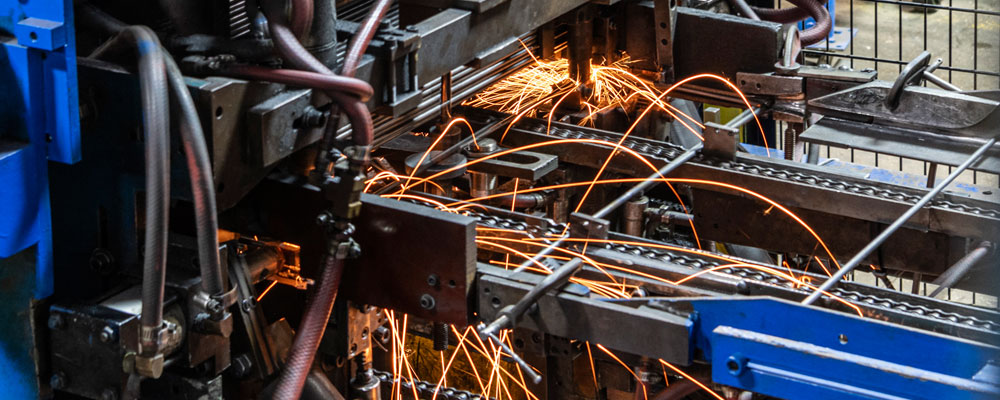

Wire Mesh Welding

Provides precise dimensions, high throughput, and resource efficiency that keeps our mesh welding capabilities in high demand.

Proudly made in America

Located in Tennessee, Kentucky and Alabama, Nashville Wire boasts in excess of one million square feet of sophisticated production and warehouse capacity. Our investment strategy ensures that new facilities are always in development. We manufacture millions of parts domestically every day.

Global Sourcing Options

Established, long-term partnerships in Asia, and a company-owned facility in Mexico enable us to provide additional fabrication opportunities, raw material sourcing, technical precision, established logistics infrastructure and blended programming.

Off-shore joint-venture partnerships provide:

- Incremental and flexible manufacturing capacity

- Blended pricing

- Container optimization

- Cross-docking coordination

- Staging and distribution scheduling

- Direct shipment options

- Established processes and procedures to ensure quality

Our partner organizations uphold the same high standards in their facilities and in the production of our products that we do. Each adheres to government regulations, stringent quality-control protocols, shared engineering platforms, environmental sustainability practices and ethical employment protocols, including the hiring of highly skilled, trained, and experienced workforce.